From Jacquard to GPUs: The Textile Origins of Computing

Weaving and computing might seem worlds apart—one ancient and tactile, the other sleek and digital—but their histories are intertwined. From punch card looms and traditional textiles to memory boards and smart fabrics, common threads run through the story of technology, threads often held by hands that have long gone unacknowledged.

The logic that underpins modern computing is literally and metaphorically woven; textile innovation threaded its way into mathematics, data processing, medicine, aerospace, and even the way your graphics card schedules work.

Jacquard Cards: The First “Program”

In 1801, Joseph-Marie Jacquard introduced a loom controlled by punch cards—rectangles of stiff paper pierced with holes that dictated which warp threads would be raised. This innovation allowed weavers to produce complex brocades without memorizing patterns or repeating them manually, dramatically increasing both efficiency and precision.

Model of a Jacquard loom with punch cards. Image: Science Museum Group

Woven cloth is formed by the interlacing of warp and weft threads. Weaving patterns are often visualized as grids showing where these threads cross over or under each other. Typically, a weaver reads each line of a pattern and manually raises or lowers warp threads accordingly. Jacquard’s punch cards automated this process: each combination of holes corresponded to a specific sequence of lifted warp threads. For the first time, the instructions for a machine's operation were stored externally, in a reusable, modular format. By 1812, more than 11,000 Jacquard looms were in use, transforming the textile industry and prefiguring the logic of modern programming.

The loom was revolutionary not just for fabric, but for the way it modeled thinking. Among those inspired by its logic was Charles Babbage, a British mathematician and inventor often called the father of the computer. Intrigued by the concept of automating complex operations through external control, Babbage carried samples of Jacquard punch cards in his coat pocket. He incorporated the same principle into his design of the Analytical Engine, a mechanical computing device capable of performing calculations based on stored instructions.

Plan diagram of Babbage’s Analytical Engine

But it was Ada Lovelace, a gifted mathematician and writer (and daughter of poet Lord Byron), who fully grasped the machine’s broader potential. In 1843, while translating a paper on the Analytical Engine, Lovelace added a series of notes that far outshone the original text. She proposed that the machine could manipulate not only numbers but symbols, producing patterns, even music, if given the right instructions. To her, it was a loom for logic. Lovelace famously wrote that the Analytical Engine could “weave algebraic patterns just as the Jacquard loom weaves flowers and leaves.”

1871 experimental design of Babbage’s Analytical Engine. Image: Computer History Museum

The idea that a physical pattern could encode and transmit instructions didn’t end with Lovelace and Babbage. It reappeared in the work of Herman Hollerith, an American inventor who developed a punch card system to tabulate the 1890 U.S. census. Hollerith’s method encoded data using holes in cards and fed them into electromechanical readers. The result? A process that had taken seven years to complete in 1880 was shortened to just a few months.

While Hollerith’s punch cards didn’t operate looms, they followed the same fundamental logic: data could be stored, processed, and interpreted by encoding it physically. His work laid the foundation for modern data processing—and for IBM, the company that would grow out of his Tabulating Machine Company.

IBM punched cards. One card contained the equivalent of a single line of code. Image: IBM

In this way, the Jacquard loom’s influence extended far beyond the textile industry. Its use of repeatable, external instructions helped establish an entirely new way of thinking about information: pattern as data, yarn as bit, cloth as computation. The loom didn’t just automate fabric—it became the conceptual prototype for the programmable machine.

Woven Memory: From Spools to the Moon

More than a century after Jacquard’s loom first punched its way into history, the logic of weaving helped launch spacecraft. In the 1960s, the Apollo Guidance Computer (AGC)—used on every crewed Apollo mission—required a form of memory that was compact, lightweight, non-volatile, and rugged enough to survive the jostling, vibration, and radiation of space travel. The solution was a remarkable technology known as core rope memory.

At first glance, core rope memory doesn’t resemble any computer hardware you might recognize. It looks more like intricate textile work: bundles of copper wire threaded through or around tiny magnetic ferrite rings, arranged with astonishing precision. These wires, stitched by hand, determined the ones and zeroes of the software. A wire threaded through a ring represented a binary 1; a wire bypassing the ring represented a 0. This created a form of read-only memory (ROM) where the program was literally woven into physical form.

Handwoven core memory. Image: Konstantin Lanzet/Wikimedia Commons

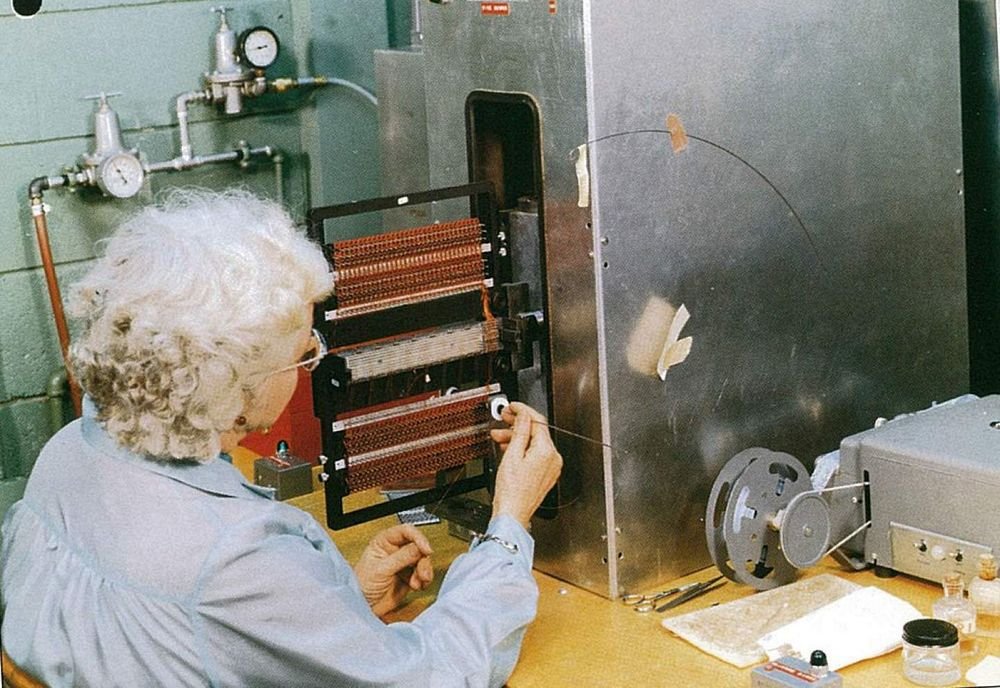

The work of creating this memory fell to women employed by Raytheon, NASA’s hardware contractor. Many came from textile backgrounds, and the job required a level of focus and dexterity on par with fine needlework. In photographs—including a striking one by Ansel Adams—you can see women seated at stations, threading delicate wire through dense fields of cores, building the code loop by loop. Engineers referred to them, half-jokingly, as “LOLs”—Little Old Ladies—though many were young and highly skilled.

What these women were doing wasn’t just manufacturing—they were programming, by hand. Each memory module contained up to 192 bits of information, and each was triple-checked for accuracy. It’s said that one misplaced wire could cause a catastrophic guidance failure. And yet, they built thousands of flawless modules. Dolores “Dee” Bracey, one of the core memory weavers interviewed later in life, said, “I had no idea what I was building—just that it was important.”

“I had no idea what I was building—just that it was important.”

The AGC flew with only 64KB of memory and a processor slower than a modern digital watch, yet it performed flawlessly. The software woven by these women controlled the spacecraft’s navigation, descent, and ascent. It guided astronauts to the Moon and brought them safely back. The poetic truth here is that the success of a lunar mission rested on something fundamentally familiar: careful, intentional threadwork.

Raytheon technician weaving core rope memory.

What’s more, this wasn’t the only time weaving logic merged with space-age tech. Core rope memory offered far higher density than the ferrite core memory used for read/write tasks. It was slow to produce but virtually indestructible once built—perfect for a one-way ticket to the Moon.

Though the contributions of these women were largely unrecognized at the time, modern historians and technologists are beginning to acknowledge their impact. The visual similarity between textile work and early hardware wasn’t accidental—it was part of a longer legacy of women's labor in computing, often under-credited and mislabeled as “nontechnical.”

In core rope memory, we see the loom evolve once again: this time not into metaphor, but into machine. Weaving, long thought to be the domain of soft goods and soft skills, became the literal infrastructure of one of humankind’s greatest technical achievements.

You can try your hand at "weaving" your own memory over at Core64—a hands-on educational kit that pays homage to Apollo's core rope memory. (Currently tops on my birthday wishlist.)

Navajo Women and the Racialization of Early Electronic Manufacturing

While NASA’s core memory modules were being assembled in Massachusetts, another form of handwork was unfolding in Shiprock, New Mexico. In the late 1960s, Fairchild Semiconductor opened a large microchip assembly plant on Navajo land, employing over a thousand Navajo women to solder and assemble some of the earliest integrated circuits.

Navajo woman working at microscope. Image: Computer History Museum

The company’s public rationale was striking: they believed that Navajo women were well-suited to the work because of their background in weaving and other traditional crafts. Executives praised their "innate dexterity," linking the precision required for soldering fine electronic components to the intricate threadwork of rugs and tapestries. On the surface, it seemed like a celebration of Indigenous skill, but beneath that framing was a more complicated and troubling reality.

As media and cultural scholar Lisa Nakamura argues in her groundbreaking essay Indigenous Circuits, this connection between weaving and electronics was used not to elevate the status of these workers, but to justify their low wages and precarious labor conditions. By casting the work as “natural” and culturally intuitive, Fairchild sidestepped the need for training, minimized recognition, and erased the technological nature of what these women were doing.

The irony is sharp: while American media in the 1960s often portrayed Native communities as "pre-modern," their labor was powering the cutting edge of modernity, feeding directly into the rise of Silicon Valley and the global tech industry. The Shiprock plant operated for about a decade before closing in the 1970s, leaving behind little formal acknowledgment of what these women contributed.

Photographs from the time show rows of women in lab coats and hair nets, hunched over circuit boards and microscopes. The tools may have changed, but the posture of concentration would be familiar to any weaver.

“The work of Indigenous women was central to the transformation of the U.S. economy from industrial to informational, yet their role has been largely overlooked.”

Like the punch card and the core memory wire, the soldered circuit board becomes another medium where textile logic meets information logic. But in this story, the labor is not only under-credited—it’s racialized, gendered, and ultimately discarded once no longer deemed cost-effective.

This section of computing history reminds us that the metaphor of weaving in technology is more than poetic. It’s political. The loom, again, is both a tool of creation and a lens for understanding whose hands build the future and whose stories are written out of it.

From GPUs to Smart Textiles

Though the loom’s influence is deeply rooted in computing history, its threads continue to surface in some of today’s most advanced technologies—including the way your computer’s graphics card processes data.

Take your computer’s graphics card. When it renders smooth motion, glowing effects, or detailed shadows, it does so using tightly coordinated bundles of parallel threads. In NVIDIA’s CUDA architecture, these bundles are called—fittingly—warps.

A warp consists of 32 threads that execute instructions in lockstep. This isn’t just poetic naming; it reflects the structural logic of parallel computing. Much like warp threads on a loom remain in tension while the weft moves across them, GPU threads stay synchronized as they work together. If one thread in the group diverges or stalls, the whole warp slows down—so harmony and alignment matter as much in code as in cloth.

Programming languages carry this textile legacy in their vocabulary: we spin up threads, weave routines together, join or detach them. Even error handling sometimes refers to threads that have been cut, broken, or unraveled. These terms persist because they reflect the deeply patterned logic required to manage concurrency and complexity in modern software. The vocabulary of weaving persists because it continues to map so naturally onto how we structure behavior, timing, and coordination in code.

“ The vocabulary of weaving persists because it continues to map so naturally onto how we structure behavior, timing, and coordination in code.”

This same logic is woven—literally—into the fabric of emerging technologies like smart textiles and e-textiles. These garments and surfaces integrate conductive threads, sensors, and sometimes microcontrollers. They flex and breathe like traditional cloth but act as interactive interfaces, measuring heart rate, tracking motion, or triggering LEDs. While the fabric itself isn’t running code, it enables code to react to physical input: motion, temperature, pressure, or touch.

Beyond fitness wearables and fashion, these fabrics are making their way into military, aerospace, and industrial applications. Researchers have developed uniforms that track soldiers’ vitals and transmit real-time data. Aircraft seats detect pressure points and adjust dynamically. Hospitals now test smart bedding that can alert nurses when a patient hasn’t moved, helping prevent bedsores and improving care. In each case, the textile itself becomes a sensor platform: soft, flexible, and intelligent.

What’s striking is that the circuitry isn’t glued on after the fact—it’s woven in. Conductive fibers, often made from silver or carbon, are integrated alongside cotton, bamboo, or synthetic yarns. They bend. They rustle. They wash and wear. New standards like IPC-8921 are being developed to ensure these smart fabrics hold up through repeated stretching, laundering, and daily use.

Pattern Thinking: Weaving as Structure and System

Look under the hood of modern mathematics and you’ll find a surprising amount of textile metaphor: knots, nets, meshes, interleaving. These metaphors aren't just poetic—they inform real models and algorithms in computer science. From mesh networks to data interleaving in digital communication, the logic of weaving continues to offer a functional blueprint for building systems, structuring information, and solving problems. Weaving offers a natural blueprint for balance, structure, and beauty. The loom gives us a way to see how seemingly chaotic threads can form a coherent whole.

From Jacquard’s punch cards to lunar navigation and smart textiles, the logic of weaving continues to thread its way through technological progress. What began as a method of organizing threads on a loom has evolved into a conceptual framework for organizing data, structure, and logic across disciplines. In every example—from code stitched into Apollo memory to warps inside your graphics card—textile thinking isn’t just inspiration. It’s infrastructure.

And yet, these connections often go unnoticed. The language of weaving persists quietly in tech, math, and medicine, shaping our tools, our metaphors, and the very structure of information systems. What might change if we saw those threads more clearly? If we acknowledged not just the logic of weaving, but the labor—and the people—who wove their way into the digital age?

Follow the Thread: Further Reading & Resources

This post touches just part of a much larger, fascinating story. Here are a few recommended resources if you’d like to explore further:

"Core Memory: Weavers of the Apollo Guidance Computer"

Science News

Read it here →

A richly detailed look at the women who built the AGC's woven memory modules by hand."Indigenous Circuits" by Lisa Nakamura

American Quarterly

PDF →

A foundational essay on Navajo women’s labor in chip manufacturing and how it was framed by race and gender."Weaving, Coding, and the Secret History of Women’s Work"

Fast Company

Read it here →

A wide-angle view of textile labor and its role in early computing."When Women Stopped Coding"

The New York Times Magazine

Read it here →

How the demographics of programming shifted from female-dominated to male-dominated—and why."Woven Memories: Core Rope Memory and the Space Race"

SparkFun Blog

Read it here →

A technically rich but approachable dive into how rope memory worked and why it mattered."Smart textiles sense how their users are moving"

MIT News Office

Read it here →

How researches developed a form-fitting fabric that recognizes the wearer’s activity.

I believe in slow craft, real connection, and thoughtful conversation. If something in this post sparked a question or memory, reach out—I’d truly love to hear from you. -Karri